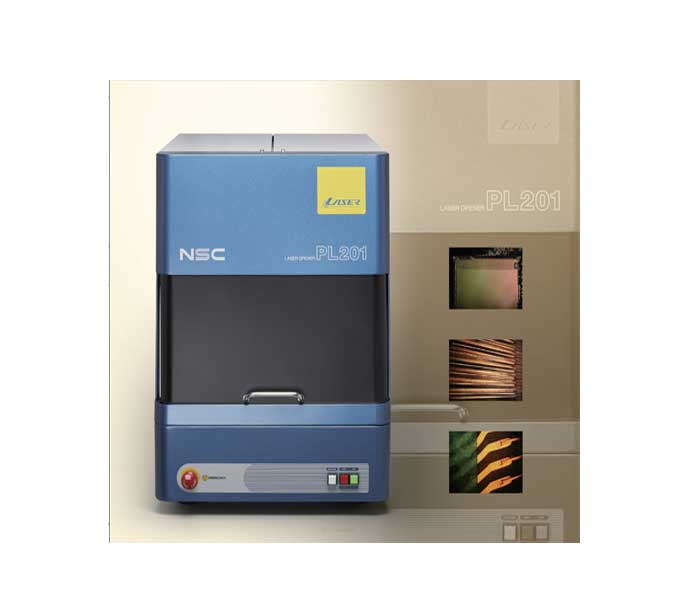

By reducing mold compound thickness on die surface to less than 100um by laser, chemical etch time can be significantly reduced, thus enabling a significant reduction in acid consumption during wet etch.

The damage on Cu and Ag wires by chemical etch can be minimized with laser operation.

Epoxy resin and solder resist can be removed by laser to expose 2nd bonding area for analysis.Laser is an effective solution to expose 2nd bonding area for packages like QFN and SOP.

By approaching from the backside of the sample, lead frame can be exposed by laser.Lead frame should be removed by Cutter or Micro shiner.

We are semiconductor equipments suppliers in Chennai (INDIA), Singapore and other countries too. Wire bonding machines, Ball bonder machines, Solder pastes, Pick 'n' Place equipments etc.,