PS Max Hub Blades series provide an advanced solution to package singulation for quality, precision and COO improvement by deliver superior product quality & value added features

New Generation Hub Blades for package singulation particularly LED (ceramic, EMC, PCB), DFN & BGA without copper lead application Package Singulation market requires a competitive solution in terms of cut quality, kerf precision and blade life consistency. By controlling of fundamental blades element (Aluminum Hub), in conjunction with newly introduced features, K&S PS Max series blades deliver superior cut quality, blade life & COO improvement to the general package singulation process.

To enable quick implementation and experienced the benefits of PS Max series blades, K&S will provide free DOE support using our application lab as well as an onsite technical support to further shorten the samples evaluation cycle to meet customer cost saving target.

The NEW Aluminum Hub designed for enabling high spindle frequency application aimed improving production throughput and extending blade life.

PS Max series blades enhancing blade straightness & parallelism control in results of much consistent kerf width for overall improvement of sawn package dimensional standard deviation.

Useful blade life of package singulation process mainly driven by 2 factors:

By achieving improved consistency of sawn package dimensional tolerance, which enables effective exposure usage and maximize useful blade life particularly on kerf sensitive or tight dimensional tolerance control application.

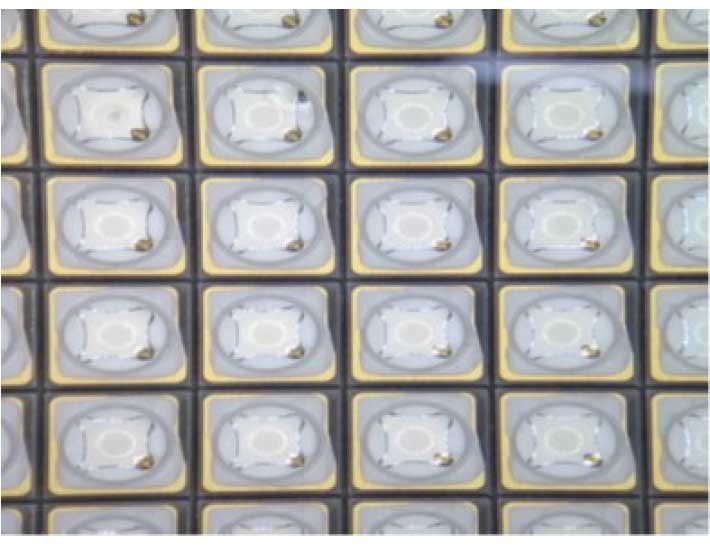

Application: Ceramic package (High power LED)

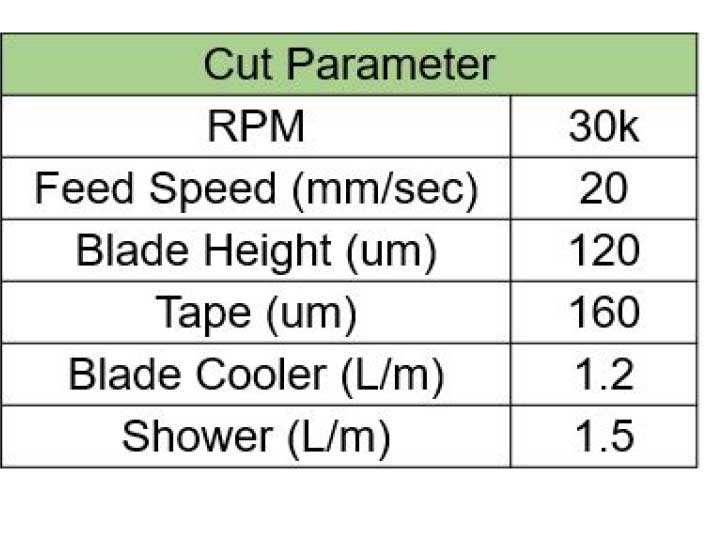

Benchmarking run: same dicer model, same package, same parameters

Results:

NEW Hub design – shiny surface with improved dynamic balance, minimize blade vibration for consistent cut performance

Supreme blade flatness – enhanced process control for consistent sawn kerf performance throughout useful life

Enhanced diamond distribution – consistent blade wears off and cut quality performance

Optional 2D barcode on blade hub for ABC system

Dispensing

We are semiconductor equipments suppliers in Chennai (INDIA), Singapore and other countries too. Wire bonding machines, Ball bonder machines, Solder pastes, Pick 'n' Place equipments etc.,