Copper bonding wires have a high purity Cu matrix and achieve their excellent processing properties by means of defined addition elements. They distinguish themselves by stable mechanical properties and the high reliability of the bonding joint, in particular as regards the reduced formation of intermetallic phases in comparison with the usual Au-Al system. They are excellent for bonding with the ball / wedge process when using a reducing protective gas atmosphere. Processing is also possible in the wedge / wedge bonding process. Copper bonding wires are, therefore, both technically and economically an alternative to gold wires. A packaging concept tailor-made for Cu wires ensures that even after storage times of up to six months the wires can be readily processed.

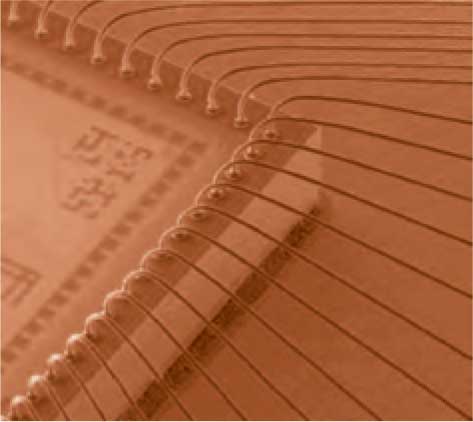

Excellent mechanical andelectrical properties allow our ultra-fine copper wires to be used in a variety of high-end, fine-pitch devices with higher lead counts and smaller pad sizes.

In addition to the significantly lower cost of copper wires, slower intermetallic growth in copper bonds provides superior reliability in high-power and discrete packages.

The relatively low cost of copper is one of the reasons for its appeal as an alternative interconnect material. By replacing gold wires with copper material, thus replacing the precious metal part, significant cost savings are possible. In applications that require increased wire diameters, the usage of copper bears a disproportionately high impact on the saving effect.

The relatively low cost of copper is one of the reasons for its appeal as an alternative interconnect material. By replacing gold wires with copper material, thus replacing the precious metal part, significant cost savings are possible. In applications that require increased wire diameters, the usage of copper bears a disproportionately high impact on the saving effect

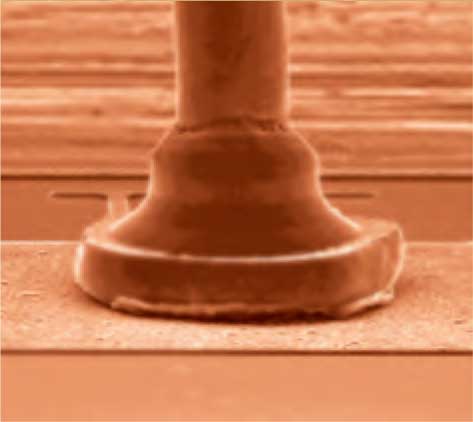

Copper exhibits significantly better conductivity than gold or aluminum. Therefore better heat dissipation and increased power ratings are attainable with thinner wire diameters. Copper possesses higher mechanical properties compared to gold. Therefore it displays excellent ball neck strength and high loop stability during molding or encapsulation

High conductivity

High tensile strength with high elongation

Good loop stability

Significantly reduced formation of intermetallic phases

Very good ball formation under protective gas

Discrete components

Semiconductor components

We are semiconductor equipments suppliers in Chennai (INDIA), Singapore and other countries too. Wire bonding machines, Ball bonder machines, Solder pastes, Pick 'n' Place equipments etc.,