Description

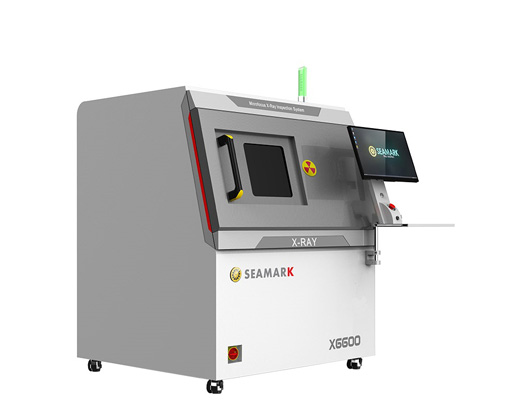

X6600 is a cost-effective general-purpose offline precision microfocus X-Ray inspection equipment. It is suitable for the inspection of various factory offline products. This AXI inspection machine has the characteristics of high magnification, multi-angle inspection, and a large-area inspection platform.

Features of X6600 Offline X-ray Inspection Machine

- Meet the needs of the general industrial X-ray machine and have a wide range of applications.

- A high-resolution design can obtain the best image in a very short time.

- Infrared automatic navigation and positioning, quickly select the shooting location.

- CNC detection mode, fast automatic detection for multi-point array.

- Oblique multi-angle inspection makes it easier to detect sample defects.

- Software operation developed by Seamark is simple and easy to use, low operating cost.

- The X-ray tube and FDP can be rotated at the same time (0-60°), making the detection image more clear and intuitive.

X6600 Offline X-Ray Inspection Machine Applications

Electronics Industry: Ideal for inspecting solder joints, PCBs, and semiconductors. Its high magnification and multi-angle inspection detect small defects like voids and cracks.

Automotive Industry: Ensures the quality of critical parts like sensors and battery cells. Its large platform supports larger items in high-volume production.

Aerospace Industry: Vital for inspecting complex components like circuit assemblies, ensuring reliability and safety by detecting internal flaws.

Medical Devices: Perfect for precision inspections of implants, catheters, and pacemakers, meeting strict safety standards.

Energy Sector: Provides high-resolution imaging to detect defects in components like insulators, transformers, and solar cells.