Description

Ultra-High Temperature Inert (Anaerobic) Gas Oven

Ultra-high temperature inert gas ovens are critical equipment in industries where high-temperature processing in an inert atmosphere is required, ensuring the quality and integrity of the materials being processed. It is applicable for atmosphere in inert gases such as Argon, Carbon Dioxide, Helium, and Nitrogen. The open-air heavy-gauge nichrome wire heater elements provide a robust heat source to up to 600 degrees. A unique dual-shell design allows for the circulation of coolant and ambient air around an inner chamber filled with inert gas, maintaining stable internal pressure and temperature.

FEATURES | Product

The ultra-high temperature anaerobic oven uses a proprietary chamber structure and sealing technology, with excellent temperature uniformity, while also ensuring higher stability and reproducibility. At the same time, the external cooling mechanism circulating by the cooling water can cool down quickly without affecting the atmosphere in the furnace, thus shortening the treatment time.

- Approved for Argon, Carbon Dioxide, Helium, and Nitrogen inert gases

- Unique inner/outer shell chamber allows coolant ambient air to circulate around an inert gas inner chamber water-Cooled Door with silicon sealing

- Temperature can rise or fall quickly, and the rise or fall rate can be adjustable

- All welded and sealed construction assures continuously low air loss

- Corrosion-resistant, stainless steel (type 304) interior

- Adjustable inert gas purge system including a flowmeter and supply connection

- Fiberglass insulation to ensure safe cabinet skin temperature

- Independent, over-temperature protection

- Circuit breaker provided for ground fault protection as standard

- High volume horizontal air recirculation system and electric heating system allow for maximum temperature uniformity in performance

- Excellent reliability and performance ratings

Parameters | Product

|

Model |

GZ-OXY-360C-A |

GZ-OXY-360C-B |

GZ-OXY-600C-A |

GZ-OXY-600C-B |

|

Temp. Range |

Room temp. +50 ~360°C |

Room temp. +100~600°C |

||

|

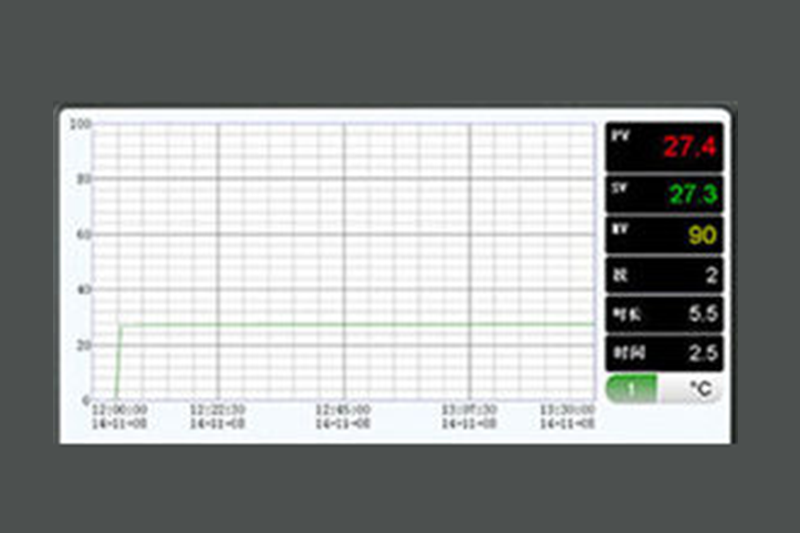

Control accuracy |

+/- 1.0°C |

+/- 1.0°C |

||

|

Temp. Distribution Accuracy |

±5°C @360°C (empty load) |

±9°C @600°C (empty load) |

||

|

Interior Dimensions HxWxD(mm) |

450x450x450 |

600 x600 x600 |

450x450x450 |

600x600x600 |

|

Exterior Dimensions HxWxD(mm) |

1540 x1090 x950 |

1720×1240 x1100 |

1750x1240x1010 |

1900x139x1160 |

|

Shelves |

2 plates |

4 plates |

2 plates |

4 plates |

|

Workspace Capacity |

91L |

216L |

91L |

216L |

|

Cooling System |

Water-cooling system |

|||

|

Control System |

LCD touch screen with PLC |

|||

|

Safety Device |

Door detector switch, overheat protector, oxygen content monitor, low water pressure detection, low gas pressure detection, fan overload detection, overcurrent ELB etc. |

|||

|

Power Supply |

3 phase AC 380V or as request |

|||

Options | Product

Shelves

Vacuum Pump

HEPA Filter

Temperature recorders (paper or paperless)

Ethernet communications

Applications | Product

- Aging

- Annealing

- Testing

- Curing

Industries | Product

- Aerospace

- Automotive

- Defense

- Electronics

- Research & Development

- Rubbers & Plastics

- Semiconductors

- Telecom

- Optical Communication

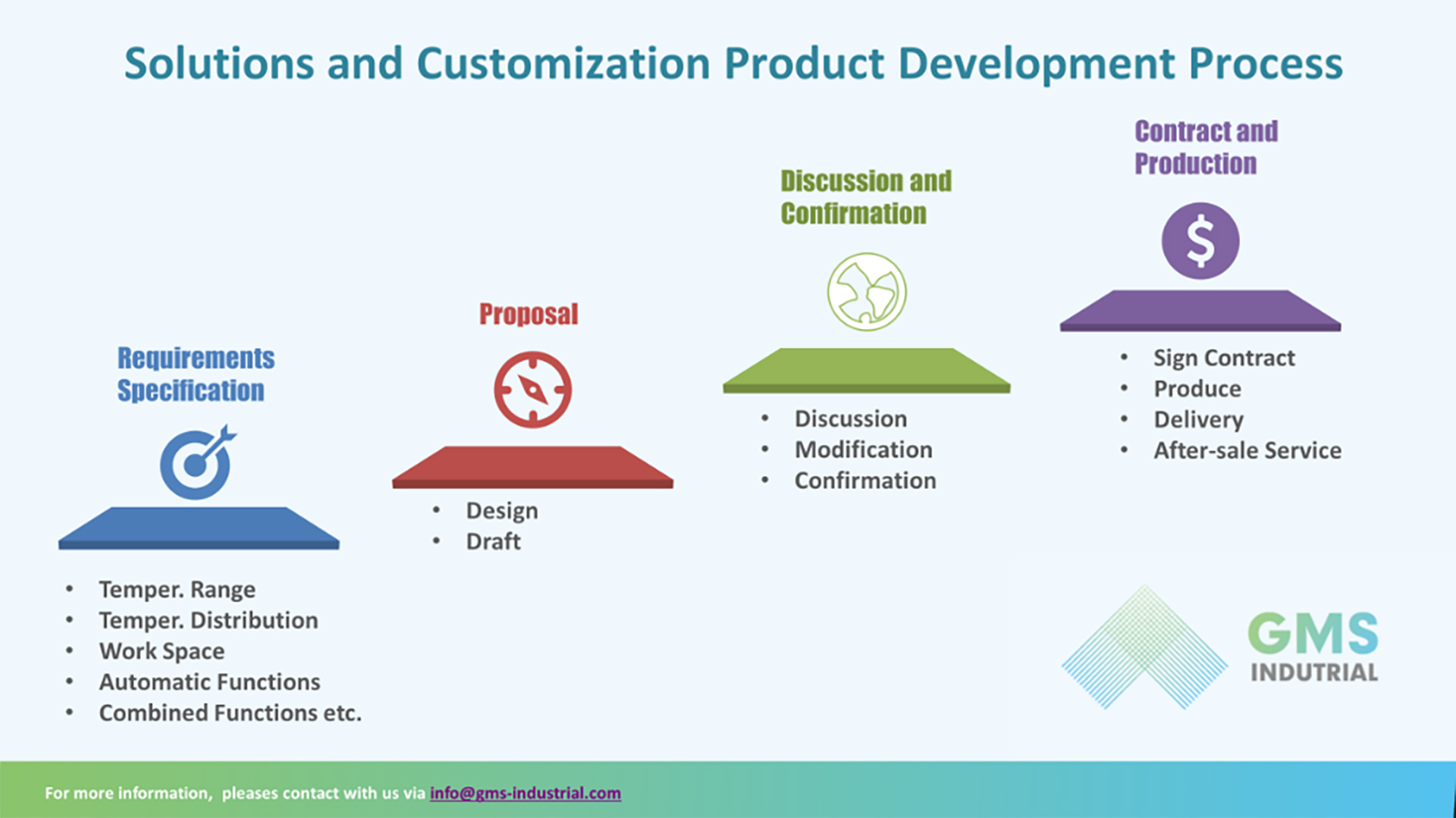

Customization | Product

GMS can provide varying levels of uniformity, size, temperature range, vacuum and automatic functions; if you have a specific tolerance or specification which must be met, please contact us with your requirements so we can ensure the equipment is designed, tested, and adjusted to meet those requirements.