Description

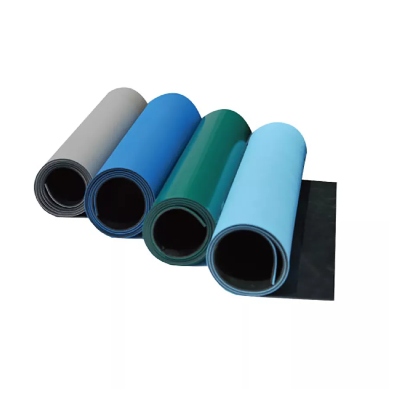

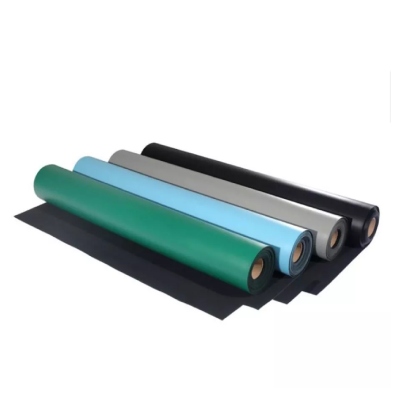

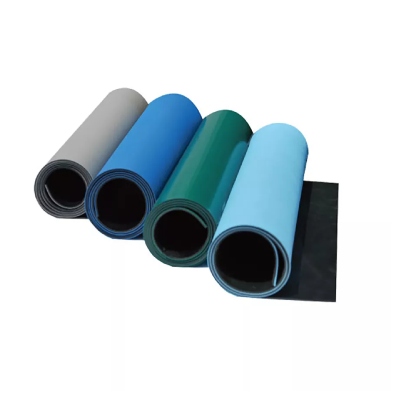

Surface Textured ESD Mat

Surface Textured ESD Mat- SK-822

ESD mats are created with durable materials(Rubber or Vinyl) for the safety of employees while working with and around electronic components and assemblies. Antistatic mats are designed to drain static charges from items placed on its surface, while protecting the surface of ESD sensitive devices.

Specification and Data

| Item Name | SK-822 |

|---|---|

| Material | Nitrile Rubber |

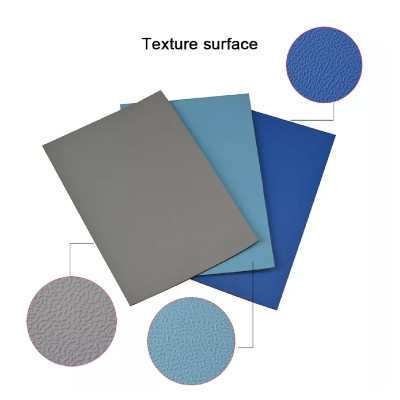

| Type | Surface texture&Bottom smooth |

| Color | Green, Blue, Grey |

| Thickness | 1.6mm/1.8mm/2.0mm or customzied |

| Top layer thickness | 0.3-0.5mm |

| Width | 0.6m,0.9m,1.0m,1.2m |

| Length | 10m,15m |

| Finish | Shiny or Dull |

| Surface resistance | 10e⁶-10e⁹ |

| Botoom reistnce | 10e³-10e⁵ |

A surface-textured ESD mat, also known as an anti-static mat, is a specialized mat designed to provide electrostatic discharge (ESD) protection in work areas where sensitive electronic components are handled. The surface texture of these mats helps to dissipate static charges and prevent the buildup of static electricity.

Here are some key features and benefits of surface-textured ESD mats

Electrostatic Discharge (ESD) Protection:

These mats are engineered to have static-dissipative properties, allowing them to control and dissipate static charges. They prevent the accumulation of static electricity, reducing the risk of ESD-related damage to sensitive electronic components.

Surface Texture:

The surface of these mats is intentionally textured or patterned, which helps to enhance their static-dissipative capabilities. The texture creates more contact points, improving the grounding and dissipation of static charges from personnel or objects placed on the mat.

Work Surface Protection:

Surface-textured ESD mats provide a protective layer for work surfaces, such as workbenches or assembly areas. They help to prevent scratches, abrasions, and damage caused by tools or equipment, while also offering ESD protection.

Chemical Resistance:

These mats are resistant to common chemicals, solvents, and oils used in industrial environments. This resistance ensures the durability and longevity of the mats, even when exposed to potentially corrosive substances.

Easy Maintenance:

- These mats are typically easy to clean and maintain. They can be wiped clean with mild cleaning solutions or anti-static cleaners to remove dust, debris, or contaminants, ensuring their optimal performance over time.

- When selecting a surface-textured ESD mat, consider the size, thickness, and overall quality of the mat. It’s important to choose a mat that meets industry standards and regulations, such as ANSI/ESD S20.20 or IEC 61340-5-1, to ensure effective ESD protection.