Description

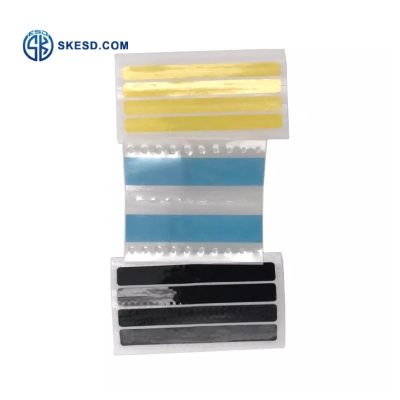

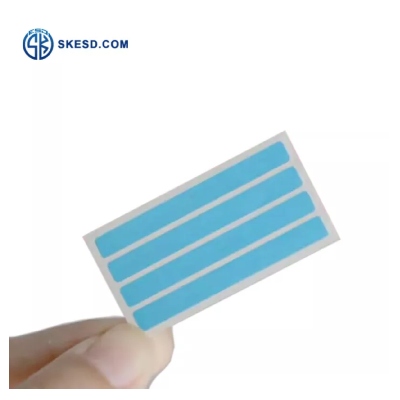

SMT Splice Tape-Single Side

SMT Splice Tape – SK-S1

SMT single splice tape is a specialized adhesive tape designed to join and secure the ends of component tapes used in SMT machines. By connecting the tapes seamlessly, it ensures uninterrupted production and minimizes downtime during assembly. Splice Tape help increase production and can be used on all SMT pick and place feeders. They provide a safe and reliable way to splice carrier tape together ensuring a precise secure join.

Specification and Data

| Item Name | SMT Splice Tape |

|---|---|

| Material | PP or PE resin |

| Size | Customizable |

| Color | Yellow, Blue, Black |

| Thickness | 2mm-6mm |

| Elongation at break | >50 |

| Loading | 2-30kg |

| Feature | High transparency, light weight |

| Application | Industrial product packaging turnover,

advertising industry, packaging industry, agricultural industry, auto parts industry Electrical industry, construction industry, etc. |

The Importance of Splicing in Surface Mount Technology

Splicing is a critical process in SMT that involves joining the loose ends of component tapes, such as carrier tapes and cover tapes. These tapes hold the electronic components in place and protect them during transportation and storage. Splicing is essential when the length of the component tape is insufficient to complete a production run. It allows manufacturers to extend the tape length and avoid interruptions in the assembly process.

The Functionality of SMT Single Splice Tape

SMT single splice tape acts as a reliable connector between two ends of component tapes. It is typically made of high-quality materials such as polyester film with a strong adhesive backing. The tape is designed to securely hold the ends of component tapes together, providing a continuous feed for SMT machines. It ensures precise component placement, reduces misalignment, and prevents tape jams or misfeeds during assembly.

Advantages of Using SMT Single Splice Tape

1.Improved Efficiency: By seamlessly connecting component tapes, SMT splice tape enables uninterrupted production, reducing the need for manual intervention and minimizing assembly line downtime.

2.Cost Savings: SMT single splice tape allows manufacturers to maximize the utilization of component tapes, reducing waste and optimizing material usage. This results in significant cost savings over time.

3.Enhanced Reliability: The secure bonding provided by SMT single splice tape ensures that components remain firmly in place throughout the assembly process, minimizing the risk of defects or failures.

4.Time-Saving: With efficient splicing, manufacturers can complete production runs without delays caused by running out of component tape. This leads to faster turnaround times and increased productivity.

Factors to Consider When Choosing SMT Splice Tape

When selecting SMT splice tape for electronic assembly, several factors should be considered:

1.Tape Compatibility: Ensure that the splice tape is compatible with the type and size of component tapes used in your assembly process. Different tapes may require different types of splice tape.

2.Adhesive Strength: The splice tape’s adhesive should provide a strong bond between the component tapes, ensuring reliability and preventing separation during assembly.

3.Temperature Resistance: Verify that the splice tape can withstand the temperatures encountered during the reflow or wave soldering processes, ensuring its durability throughout assembly.

4.Ease of Application: Choose splice tape that is easy to handle and apply, facilitating smooth and efficient splicing operations.

Best Practices for Applying SMT Splice Tape-Single Side

To ensure optimal results when using SMT single splice tape, follow these best practices:

1.Clean the Surface: Thoroughly clean the component tape ends before applying the splice tape to ensure proper adhesion and eliminate any contaminants that could affect performance.

2.Align and Secure: Align the component tape ends precisely and securely attach the splice tape, ensuring that it covers the entire width of the tape to prevent any misalignment during assembly.

3.Proper Tension: Apply the appropriate tension when joining the component tape ends to maintain a consistent and reliable feed through the SMT machine.

4.Quality Inspection: Regularly inspect the splice tape connections during production to identify any issues or potential defects and take corrective actions promptly.