Description

Inert (Anaerobic) Gas Oven

GMS inert gas ovens are designed for durability and performance. Inert gas ovens are ideal for industrial oven applications that involve processing materials in a controlled atmosphere environment, including moisture drying, wafer drying, epoxy curing, and aging of electronic components and devices. The GMS inert gas oven utilizes a high-volume horizontal air recirculation system which maximizes temperature uniformity and performance.

Ensure effective heating while protecting samples from oxidation with GMS’s selection of Inert Gas Ovens. Confidently work on temperature tests and heat treatments in a non-oxidizing environment with inert gas ovens that supply controllable and non-flammable N2 within the chamber.

Features | Product

- All welded and sealed construction assures continuously low air loss

- Corrosion-resistant, stainless steel (type 304) interior

- Baked on white powder-coated finish on the exterior for long-lasting corrosion protection

- Adjustable inert gas purge system including a flowmeter and supply connection

- Fiberglass insulation to ensure safe cabinet skin temperature

- Independent, over-temperature protection

- Circuit breaker provided for ground fault protection as standard

- Compact vertical design

- High volume horizontal air recirculation system and electric heating system allow for maximum temperature uniformity in performance

- Excellent reliability and performance ratings

Options | Product

- Oxygen concentration indicator

- Temperature recorders (paper or paperless)

- Reverse door hinge

- Programmable controller, Ethernet, and USB communications

- Clean room packaging for shipment and installation

- Data logging and trending

Applications | Product

- Aging

- Annealing

- Testing

- Curing

- Drying

- Solvents, Coatings, and Paint Curing

- Stress-Relief

Industries | Product

- Aerospace

- Automotive

- Defense

- Electronics

- Research & Development

- Rubbers & Plastic

- Semiconductors

- Telecom

- Optical Communication

Customization | Product

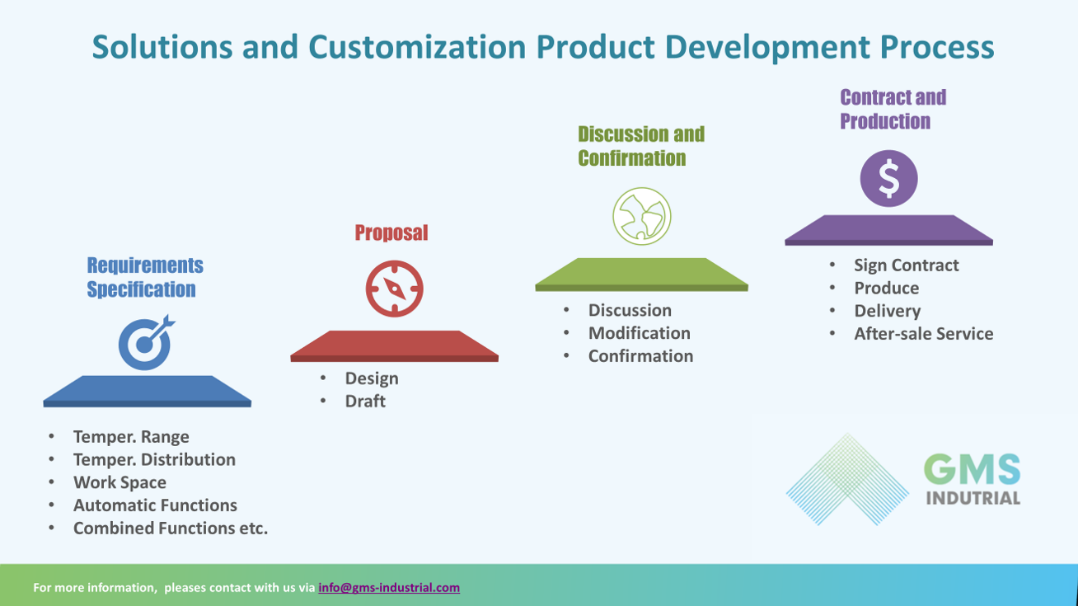

GMS can provide varying levels of uniformity, size, temperature range; if you have a specific tolerance or specification which must be met, please contact us with your requirements so we can ensure the equipment is designed, tested, and adjusted to meet those requirements.

Packaging & Shipping |Product

Packaging:

Export wooden standard package. (non-log, non-solid wood, no fumigation, meet export standards)

Shipping:

Service:

Product Parameters | Product

|

Model |

GZ-OXY-2SH (2 independent controlled work space) |

GZ-OXY-02 |

|

|

Pictrue |

|

|

|

|

Oxygen Control Level |

≤100PPM |

||

|

Temp. Range |

Room temp. +20~250°C |

||

|

Control accuracy |

+/- 1.0°C |

||

|

Temp. Distribution Accuracy |

±2°C (at 100°C), ±3°C (at 200°C) |

||

|

Temp. Rising Time |

About 25min (Room temp.→150°C). empty chamber |

||

|

Operation Function |

Optional for fixed temp. or program operation |

||

|

Interior Dimensions |

600x720x600(mm) |

910x620x620(mm) |

|

|

Exterior Dimensions |

1805 x 1340 x 865 (mm) |

1750x855x1030(mm) |

|

|

Workspace Capacity |

259L*2 |

350L |

|

|

Shelves |

2 Shelves for each chamber Distance can be adjusted (Extra Shelves can be offered as requested) |

4 Shelves Distance can be adjusted (Extra Shelves can be offered as requested) |

|

|

Cooling System |

Air cooling system or Water-cooling system |

||

|

Inert Gas Source |

≥Flow 150L/min, 0.3-0.4MPA |

||