Description

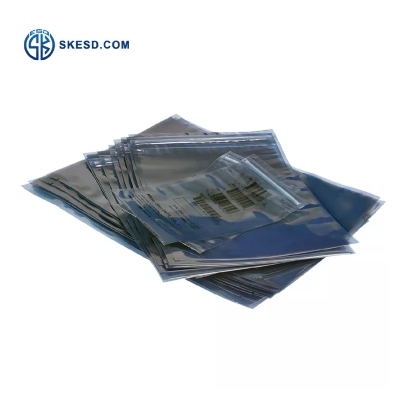

ESD Protective Shielding Bag for Electrical Components

ESD Shielding Bag – SKD01

Esd bag, The ESD shielding bag has good anti-static and electrostatic shielding performance. It can form a Faraday cage induction cover effect in the bag to prevent electrostatic accumulation and avoid electrostatic damage to internal sensitive electronic products. At the same time, it can also shield external personnel and equipment from ESD electrostatic discharge.

Specification and Data

| Item Name | SKD01 |

|---|---|

| Material | APET + CPP |

| Color | Semi Transparent |

| Outer Size | 3”*3”, 4”*4”, 5”*5”, 6”*6”, Customize |

| Thickness | 0.075mm |

| Sealing Style | Zip Lock / Open Top |

| Sealing Sides | 2 Sides / 3 Sides |

| Printing | Without / Customized |

| Surface Resistance | 10e⁶-10e⁹ |

| Shielding Energy | <20nJ |

| Testing Standard | ANSI/ESD STM11.11

ANSI/ESD STM11.31 |

What is an ESD Shielding Bag?

An ESD shielding bag, also known as an anti-static bag, is a specialized packaging material designed to prevent electrostatic charges from damaging sensitive electronic devices. These bags are made from materials with low or no electrical conductivity, ensuring that any static charges generated by external sources or human touch are safely dissipated.

How Does an Anti-static Shielding Bag Work?

Anti-static shielding bags work by providing a Faraday cage effect, which means they create a barrier that blocks external electric fields from entering the bag. The bag’s conductive material allows any static charge present on the device or generated inside the bag to be distributed evenly across its surface and discharged through grounding points, effectively neutralizing the charge.

Types of ESD Protective Shielding Bags

ESD Protective shielding bags come in various types, each offering different levels of protection based on the specific requirements of the electronic components being stored or transported. The common types include:

Metalized Shielding Bags: These bags have a metalized film layer that provides excellent ESD protection by creating a barrier against electric fields.

Static Shielding Bags: Made from multiple layers of metalized polyester, these bags offer superior protection against ESD, electromagnetic interference (EMI), and radio frequency interference (RFI).

Conductive Bags: These bags are constructed using a conductive material, such as carbon-filled polyethylene, and are primarily used for storing devices that are sensitive to static charges.

Moisture Barrier Bags: These bags combine ESD protection with moisture resistance, safeguarding electronic components from both static discharge and moisture damage.

Benefits of Using ESD Shielding Bags

Using ESD bags provides several key benefits for electronic components and devices:

ESD Protection: ESD static shielding bag bags effectively dissipate static charges, safeguarding electronic components from potential damage.

Contamination Prevention: The bags also act as a barrier against dust, dirt, moisture, and other contaminants that could harm sensitive electronics.

Extended Shelf Life: By protecting components during storage and transportation, Anti static shielding bags help extend the shelf life of electronic devices.

Compliance with Industry Standards: Many industries, such as aerospace, automotive, and medical, have specific ESD protection requirements. Using ESD bags ensures compliance with these standards.

Proper Handling and Usage of ESD Shielding Bags

To maximize the effectiveness of esd static shielding bags, it’s important to follow proper handling and usage guidelines:

Ensure Clean Environment: Work in a clean, static-controlled environment when handling ESD-sensitive components and bags.

Grounding: Ground yourself properly by wearing an ESD wrist strap or using an ESD grounding mat before handling ESD shielding bags or electronic devices.

Seal Integrity: Check the bags for any damage or holes that may compromise their effectiveness. Only use bags with intact seals.

When selecting an ESD bag, consider the following factors:

Size and Dimensions: Choose a bag that can accommodate the size of the electronic component while providing enough space for proper sealing.

Level of Protection: Assess the sensitivity of the component and select a bag that offers the appropriate level of ESD protection.

Compatibility: Ensure that the bag material is compatible with the specific requirements of the component being stored.

Quantity: Determine the quantity of components to be stored or transported and select the appropriate size and packaging options.