Description

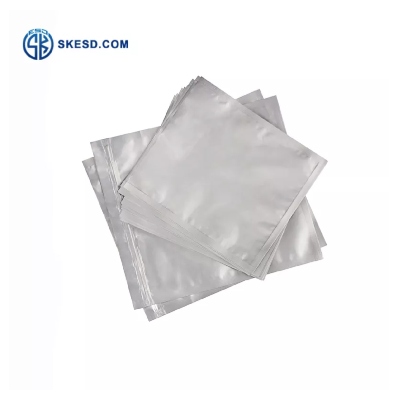

ESD Moisture Barrier Bag for Electrical Components

ESD Moisture Barrier Bag – SKD11

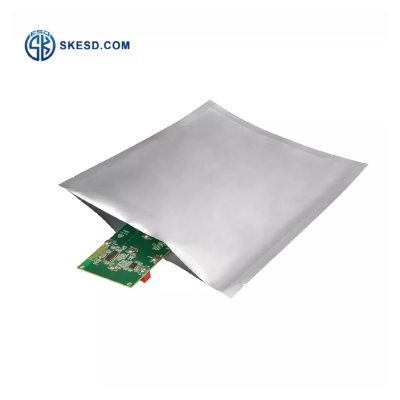

Esd bag,The ESD Moisture Barrier Bag is made of PET, AL and PE, and the inner layer is pure metal aluminum. It has good waterproof, oxygen-resistant, light-proof, puncture-resistant and great electrostatic protection. The Faraday cage effect formed by the bag can effectively isolate the item from the external electrostatic field, avoid the generation of static electricity in the bag, and protect the sensitive components from potential electrostatic hazards. This product is suitable for packaging of electronic products with moisture-proof requirements, such as various types of PC boards, IC integrated circuits, optical drives, hard disks, etc.

Our high-quality Moisture Barrier Bags protect sensitive equipment and products from both electrostatic discharge damage (ESD) and moisture damage during shipping and storage. Suitable for vacuum-sealing, these bags offer maximum resistance to vapour and oxygen. In addition, the opaque and light-tight material ensures that the contents cannot be seen from outside, offering additional security.

Specification and Data

| Item Name | SKD11 |

|---|---|

| Material | APET+AL+PE |

| Color | Silver |

| Outer Size | 3”*3”, 4”*4”, 5”*5”, 6”*6”, Customize |

| Thickness | 0.12mm |

| Sealing Style | Zip Lock / Open Top |

| Printing | Without / Customized |

| Surface Resistance | 10e⁶-10e⁹ |

| Shielding Energy | <20nJ |

| Testing Standard | ANSI/ESD STM11.11

ANSI/ESD STM11.31 |

Antistat Moisture Barrier Bags, protect sensitive electronic components against moisture and static damage during storage or transportation. The bags are opaque and light-tight ensuring the contents cannot be seen from the outside, adding operational security to their functionality. These moisture barrier bags are suitable for packing of electronic products that are sensitive to moisture, static e.g. plus PCBs or integrated circuits. The puncture-resistant and moisture-proof packaging has a flexible structure and is also suited for vacuum-sealing.

FEATURES AND BENEFITS

1.Firm lamination and hot sealing offer superior resistance of vapor and oxygen

2.Surface resistance of 108 – 1011Ω

3.Flat open top style with a printable surface

4.Flexible structure, easy to vacuum seal

5.Customised printing is available

6.Minimum order quantities may apply for some sizes