Description

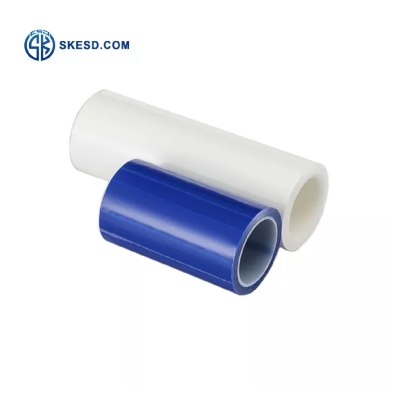

Effective PE Adhesive Sticky Rollers in Blue and White

Item No.:SK-RL

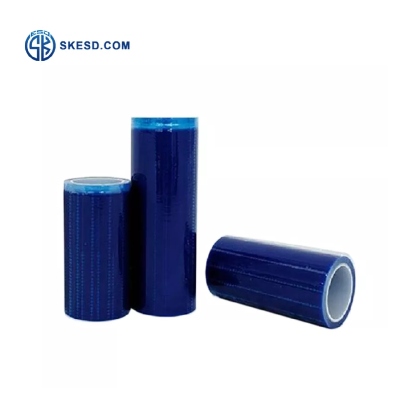

Sticky rollers is made by rolled-up PE sheets. They are perforated at regular intervals for easy peel and dispose. Each disposition will provide a new adhesive surface for next use.The sticky rollers are mainly used in cleanroom environments. Its soft surface texture ensures the removal of the contamination without traces or scratches on the surfaces of PCB, desktops, equipment panels…Sticky rollers eliminate the needs to clean via wiping, mopping or even sweeping of floors and general areas.

Specification and Data

| Item Name | Sticky Roller |

|---|---|

| Material | PE film+ water based acrylic |

| Type | Left edge or No Left edge |

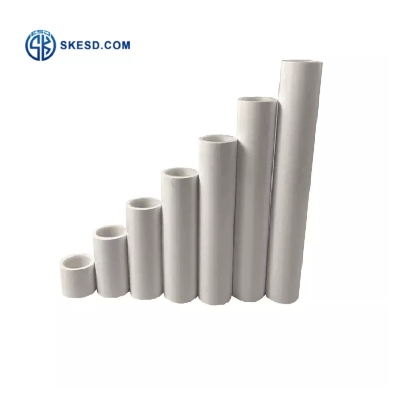

| Width | 4/6/8/10/12″ (inch) |

| Color | Blue ,White |

| Adhesive thickness | 23±2g/sqm |

| Adhesive strength | 0.130-0.170KN/m |

| Length | 16/18/20meter |

| Diameter | outer 54mm , inner 38.2mm |

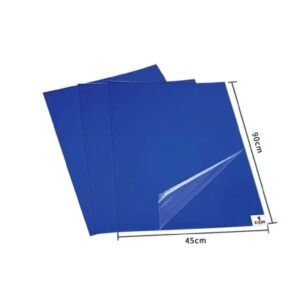

| Thickness | 0.045mm |

| Adhesive | High |

| Application | remove the dust from the surfaces of PCB, desktops, equipment panels… |

Disposable sticky roller sheets are pre-perforated and can be easily removed when saturated with contaminants.

When the roller becomes too soiled to pick up any more contaminants, simply peel off the dusted layer and tear off at the perforations to expose a new sheet of adhesive films.

When the roll is used up, simply slide it off the handle and replace with a fresh roll.

It is quick and effective at removing various contaminating particles from floors, ceilings, walls, table tops and other surfaces.

| Items | Application |

| PP sticky rollers | PP Sticky Rollers are used for machines, normally used with silicone rollers |

| PE sticky rollers | PE Sticky Rollers are used for easily remove dust, dirt and particulate from surfaces in clean room, such as walls, ceilings and other hard to reach areas. |

| Silicone Sticky Rollers | Silicone Sticky Rollers are mainly used in Electronics, Semi-conductors, PCB, LCD, SMT, Computer, etc fields for removal contaminants. They are popular cleaning tools for sensitive components in electronics manufacturing. |

2, The standard core diameter sizes are designed to allow maximum effectively clean wide or narrow areas with less frequent sheet disposal.

3, Particulates are limited by the lifting action of the roller as it passes over the surface.

4, The adhesive on the tacky film not only removes contaminants but also provides an inhibitor to prevent microbial growth, which makes it suitable even for non-cleanroom use.

2. Large surface remove small dust and powder wherever you roll;

3. Easily replace dirty layers by finding the perforated edge and just tearing it off;

4. Ideal for industrial usage

2.To use the roller flexibly,which can be use together with handle.

3.It will be easy to clean floor or roof to be with the expansion pole