Description

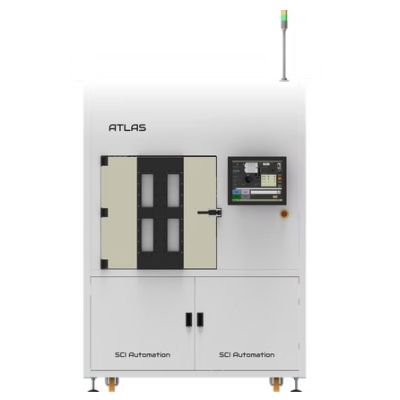

Atlas is a flexible, standalone batch plasma cleaning system. It can be used consistently in a manufacturing environment to clean and activate the surface of oddly shaped parts.

Atlas is the big brother of the Juno system and can process much bigger products. Its plasma chamber design also includes simple shelves that can be arranged at different heights to allow multiple products sizes. Each shelf can be either:

-

connected to the RF signal to deliver a RIE (Reactive Ion Etching) plasma process or,

-

grounded to deliver a PE (Plasma Etching) plasma process

This allows to carefully select the plasma energy levels and treat sensitive products.

Atlas has a specific gas distribution system that allows optimal gas flow and plasma reach inside complex geometries that may occur in the products to be treated.

Atlas is typically used for:

-

Plasma cleaning before wire-bonding on modules

-

Plasma cleaning before transfer molding on modules

-

Plasma cleaning before under-fill

-

Plasma cleaning on PCBs, BGA substrates

Atlas’s versatility extends to a wide range of applications within the Semiconductors, Automotive and Electronics industries.

Product Specifications

Machine type – Standalone batch plasma cleaner or desmearing system

Footprint – 1503W x 1820L x 2101H mm

Plasma chamber configuration- 4 shelves with 4 couples of powered electrode and ground electrode OR 4 holders for PCB desmearing

Max product size – 500W X 520L X 625H mm

Min product size – N/A

Plasma generator – 600W RF Generator 13.56 MHz

Automatic tuning system or

5kW generator at 40 kHz

Gas Lines – 2 Process gas lines with Mass Flow Controller

1 Purge line

Pumping system – Dry vacuum pump 1670 L/min or

Dry vacuum pump 1830 L/min plus booster pump at 8400 L/min

Controller – Win10 LTSC PC with fieldbus

21″ Touchscreen

Proprietary SCI software

Facilities – Single phase 110-240V 50/60 Hz

CDA 5 to 6 bar

Process gas pressure 0.5 to 1.5 bar

Exhaust port 40 mm OD

Certifications – CE, S2, S8, Cleanroom ISO7 (10k)

Options – Dry vacuum pump 5000 L/min

Kit for using pure hydrogen and hydrogen generator