Description

PP Sticky Roller for Cleanroom Dust Remove

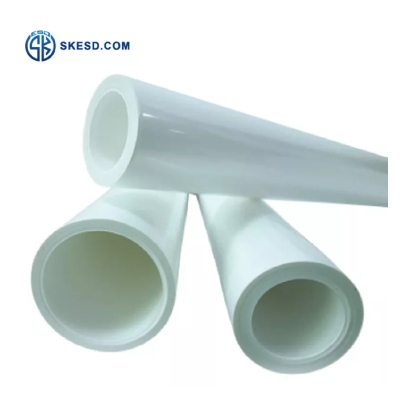

Item No.:SK-RMP

Sticky rollers is made by rolled-up PP sheets. They are perforated at regular intervals for easy peel and dispose. Each disposition will provide a new adhesive surface for next use.

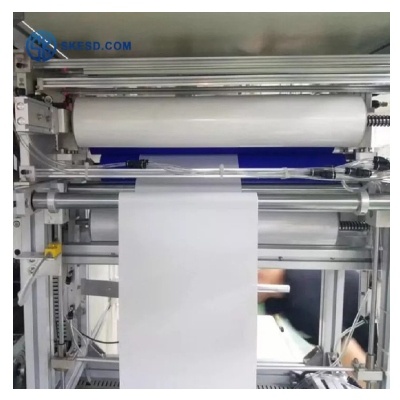

The sticky rollers are mainly used in cleanroom machine. Its soft surface texture ensures the removal of the contamination without traces or scratches on the surfaces of machine, desktops, equipment panels…Sticky rollers eliminate the needs to clean via wiping, mopping or even sweeping of floors and general areas.

Specification and Data

| Item Name | PP Sticky Roller for Machine Use |

|---|---|

| Material | PP film |

| Type | with cut line and without cut line |

| Width | 65/90/130/170cm or customize |

| Color | White |

| Length | 20m |

| Inside Diameter | 3 inches (7.62cm) |

| Thickness | 80um |

| Viscosity | 400, 800, 1200D |

| Application | remove the dust from the surfaces of Machine, desktops, equipment panels… |

The Power of the PP Sticky Roller

Adjustable Tackiness for Customized Cleaning

The PP Sticky Roller its ability to adjust tackiness according to specific cleaning needs. This feature ensures that the roller can effectively remove particles and contaminants of varying sizes and adhesion levels. Whether you are dealing with fine dust particles or stubborn impurities, the PP Tacky Roller can be tailored to deliver optimal cleaning performance, meeting the unique demands of different industries.

Versatility in Particle Removal

With its advanced design, the PP Sticky Roller for cleaning machines is a versatile tool capable of removing various types of dirt, dust, impurities, and particles encountered in the PCB manufacturing and related industries. From PCT and FPC to LCD processing, LGF, and flexible precision printing, this roller ensures thorough cleaning without causing any damage to the delicate components or surfaces. Its gentle yet effective adhesive properties make it an indispensable tool for maintaining the integrity and performance of electronic devices.

Applications of the PP Tacky Roller

PCB Manufacturing

In the PCB manufacturing process, the PP Sticky Roller plays a crucial role in eliminating contaminants and particles that may compromise the functionality and reliability of electronic circuits. Whether it’s removing excess solder paste, dust, or other debris, the roller provides a reliable and efficient solution, ensuring the production of high-quality PCBs.

FPC and LCD Processing

Flexible Printed Circuit boards (FPC) and LCD (Liquid Crystal Display) processing require meticulous cleanliness to maintain the integrity and performance of these sensitive components. The PP Tacky Roller excels in removing particulate matter that may affect signal transmission, display quality, or overall functionality. Its gentle touch and customizable tackiness make it a trusted tool in these industries.

LGF and Precision Printing

Industries involved in LGF (Light Guide Film) and precision printing rely on the PP Sticky Roller for achieving impeccable results. By eliminating particles and impurities that could affect light transmission or printing quality, the roller ensures consistent and flawless output. Its ability to adapt to different particle sizes and adhesion levels makes it an invaluable asset in these precision-driven applications.

Cleanroom Use

Cleanroom sticky rollers are essential tools in cleanrooms, which are controlled environments used in industries like semiconductor manufacturing, pharmaceuticals, biotechnology, and electronics. The rollers help maintain the cleanliness of surfaces within the cleanroom, preventing the introduction of contaminants that could compromise products or experiments.