Description

Automatic Oven with Code Scanning Function

The automatic Scan-Code Oven is a multifunctional automated baking device. It features automatic door opening and closing, enabling close collaboration with AGVs or wafer handlers for automated material handling, while also supporting manual loading and unloading. With four independent chambers, each equipped with a touchscreen for customized parameter settings, the oven can meet diverse production needs. A scanning chamber is integrated to bind materials during loading and unloading, automatically retrieving baking recipes to ensure process accuracy. Moreover, it can be connected to a host computer for local data storage and processing, and communicate with the MES system to achieve intelligent production control. This makes it widely applicable in semiconductor and other fields, enhancing production efficiency and product quality.

Technical Features | Product

- Automatic door opening and closing allow collaboration with AGVs or wafer handlers for automated material handling, while also supporting manual operations to meet various production needs.

- Four independent chambers, each with a touchscreen for customized parameter settings, can handle different products and processes, improving equipment utilization.

- A scanning chamber binds materials during loading and unloading, automatically retrieving baking recipes to ensure process accuracy, enabling precise product tracing and process management.

- It can be connected to a host computer for local data storage and processing, and communicate with the MES system for intelligent production control.

- It can meet large – scale automated production needs, while also being suitable for small – batch trial production or manual operations in special cases, offering high applicability and flexibility.

Application Fields | Product

- In chip manufacturing, it plays a key role in thin – film deposition and photoresist baking, enhancing semiconductor production efficiency and quality.

- In electronic component production, such as PCB baking, it ensures component performance and reliability.

- In battery production, it improves consistency and stability in electrode baking, boosting battery performance.

- In optical lens coating, it ensures imaging quality and optical performance through pre – baking.

- In mechanical part processing, it improves dimensional accuracy and mechanical properties through stress – relieving baking.

- In biomedical material production, such as medical consumable baking, it ensures material performance and quality.

Options | Product

Chillers

Vacuum pumps

Vacuum Gauge

MFC

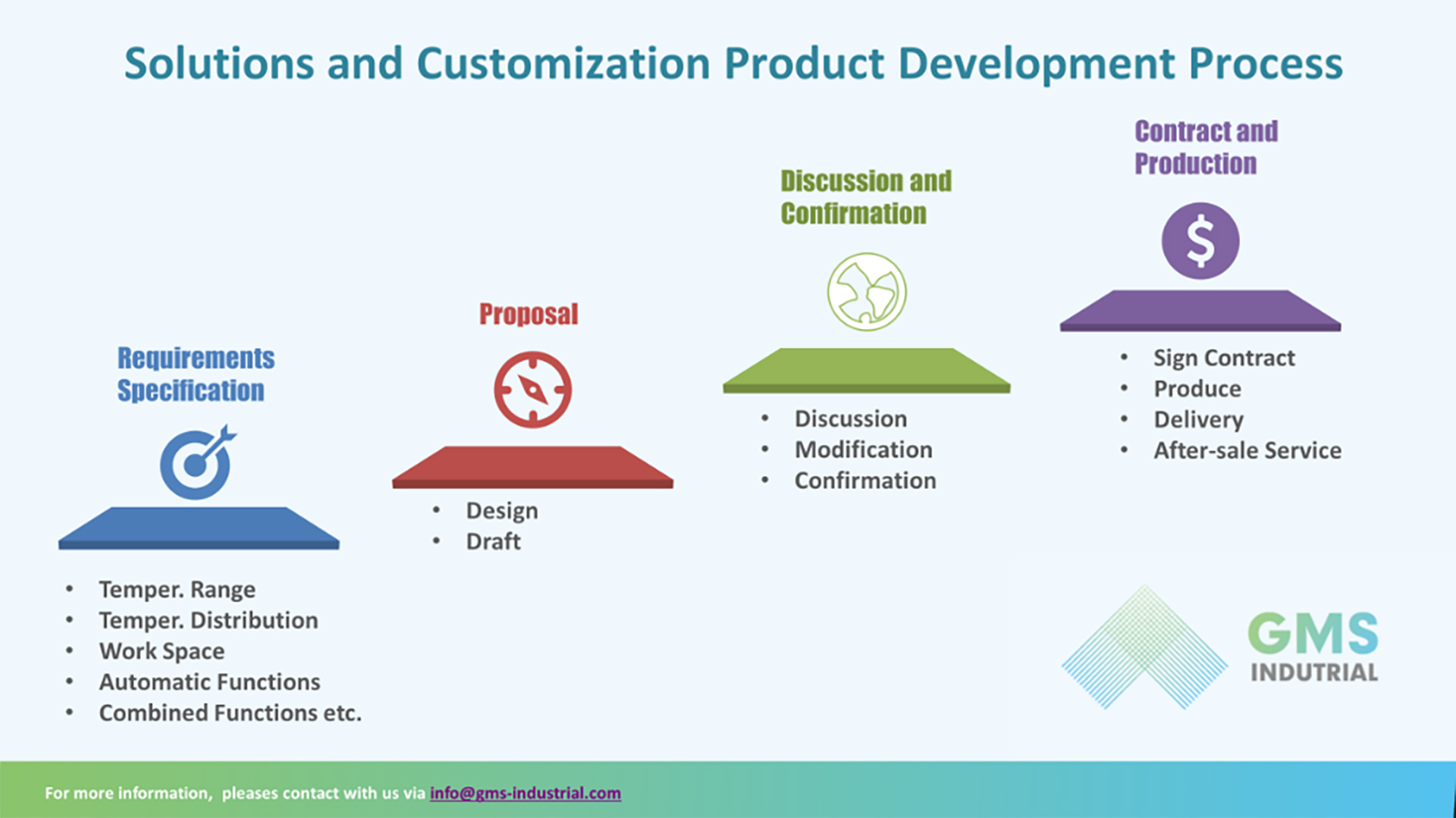

Customization | Product

GMS can provide varying levels of uniformity, size, temperature range, vacuum and automatic functions; if you have a specific tolerance or specification which must be met, please contact us with your requirements so we can ensure the equipment is designed, tested, and adjusted to meet those requirements.