Description

Automated Double-Layer Tunnel Oven System

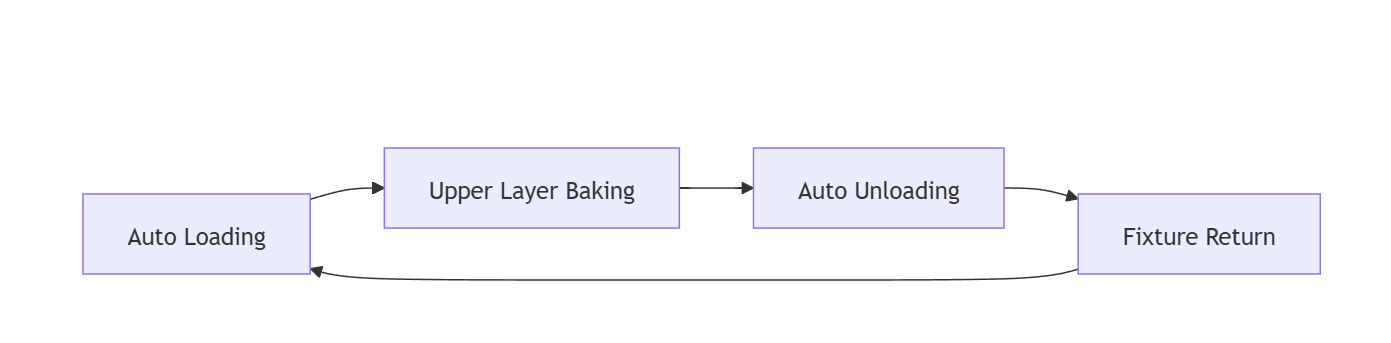

This tunnel oven features a dual-layer design with integrated fixture loading/unloading and automated return functionality. At the infeed section, the system synchronizes with upstream automation equipment to precisely load products onto fixtures. These fixtures then transport products through the heating tunnel for controlled baking.

The discharge end incorporates downstream automation for product unloading, after which fixtures are automatically transferred to the lower return conveyor. The fixtures efficiently cycle back to the tunnel entrance for reloading, completing a continuous production loop.

By seamlessly connecting baking processes with automated material handling, this system achieves fully automated production line integration, delivering significant efficiency improvements of 30-50% compared to conventional systems.

Key advantages:

- Closed-loop fixture circulation eliminates manual handling

- Perfect synchronization with upstream/downstream equipment

- 24/7 continuous operation capability

- Production capacity: 150-1200 units/hour (configurable)

Key Features | Product

1.End-to-End Automation

2.Precision Baking Solution

Standard Work Cycle | Product

Technical Specifications | Product

| Parameter | Specification |

| Standard Output | 150-1200 pcs/hr (based on product size) |

| Fixture Cycle | ≤110 sec/turn |

| Thermal Efficiency | 35% improvement vs single-layer ovens |

Customization | Product

GMS can provide varying levels of uniformity, size, temperature range; if you have a specific tolerance or specification which must be met, please contact us with your requirements so we can ensure the equipment is designed, tested, and adjusted to meet those requirements.

Features | Product

●Heavy-duty exterior with heavy-gauge, reinforced, cold-rolled steel

●Horizontal and vertical conveyor oven designs to maximize airflow

●Customize designed based on curing applications for materials such as plastic, varnish, rubber and epoxy

●Variety of configurations including flat conveyor belt style, teflon conveyor belt, carbon steel conveyor chains and more

●State-of-the-art digital controllers

●Optional items such as access doors, lighted viewing ports and light beam sensors

●Temperature ranges from 100℃ to 500℃

●Sizes are customizable based on requirements and production volume

●Automatic lifting or loading functions based on requirements and production line status

●Baked on white powder-coated finish on the exterior for long-lasting corrosion protection

●Adjustable air exchange system which allows fresh air to flow into the oven and exhaust gas get out of the oven

●Aluminum silicate insulation to ensure safe cabinet skin temperature

●Excellent reliability and performance ratings

Options | Product

Applications | Product

●Aging

●Testing

●Curing

●Drying

●Solvents, Coatings, and Paint Curing

●Stress-Relief

Industries | Product

After-Sale Service | Product

Installation and comprehensive training of your staff are key to ensuring that your equipment operates properly. GMS Industrial Oven Installation offers a variety of installation and training options to ensure your equipment has a long productive life. Remote guidance, through email, instant messaging apps, phone call, face-to-face video, on-site guidance supports are all available for various clients