Description

High Temperature Vacuum Oven

Vacuum ovens are ideal for removing residual water, solvents or other volatile compounds from temperature-sensitive products. The principle of operation, essentially, is to remove unwanted molecules by lowering the pressure in the oven (creating a vacuum). When the oven pressure reaches the desired vapor pressure of the contaminants, these contaminant molecules evaporate, turn to vapor, and are removed from all areas of the product. This drying is accomplished without the use of excessive heat. This makes vacuum drying suitable for materials that become damaged or are changed if exposed to high temperatures. Vacuum drying also minimizes the risk of scaling and the formation of oxidation residues. Vacuum high temperature ovens are typically used for products that are not heat resistant and are temperature sensitive. This type of oven is widely used in semiconductor, MEMS, electronic area.

Features | Product

- Easy to operate, fixed value operation, program operation, quick auto stop proceeding, auto stop operation, auto start operation can be realized.

- Temperature control is PID mode touch screen instrument, single point type or program type temperature control, can be automatically calculated, PV/SV display at the same time, point touch setting, with memory function (such as temperature, time).

- Digital setting can be realized by special function menu key and up/down key. Program controller with repeat function, divided into 3 segments and 30 steps.

- With self-diagnostic circuit (temperature sensing abnormality, heater disconnection, automatic over-rise prevention, SSR short circuit), over-rise preventer, leakage protection switch to prevent over-current, key lock and other safety functions.

- Through the auxiliary menu key, it can realize the operation of over-rise prevention question, deviation correction and key lock setting.

- Vacuum control mode automatic control, reach the vacuum degree to stop vacuuming, below the lower limit automatically start, so that the cycle of work, constant temperature time is completed, stop working; manually unpressurized air or nitrogen filling.

- Provide standard and customized functions in a variety of sizes and temperature ranges.

Options | Product

- Oily scroll pumps

- Dry scroll pumps

Customization | Product

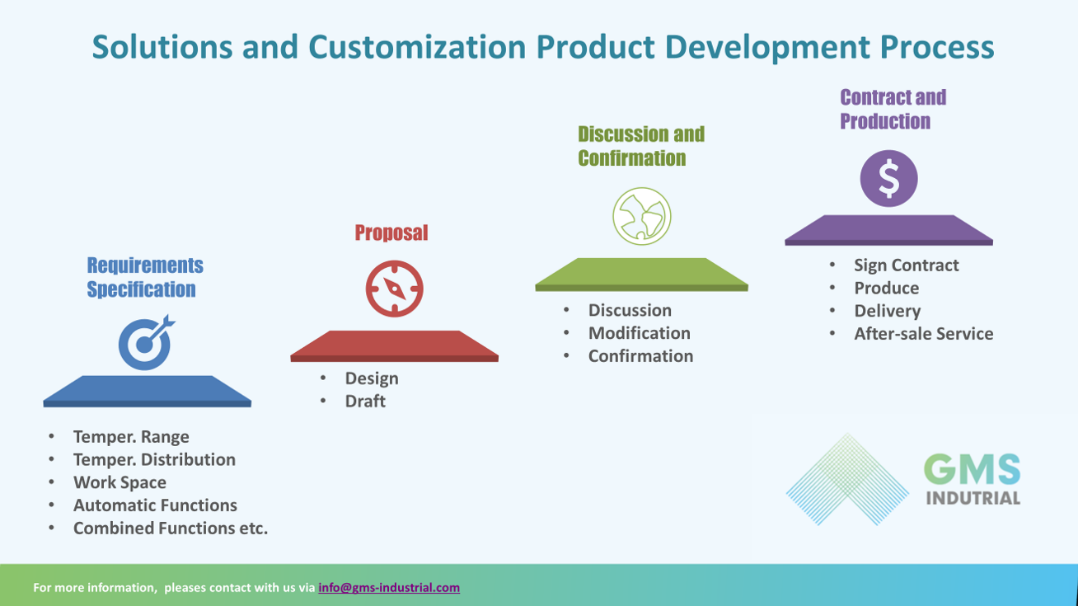

GMS can provide varying levels of uniformity, size, temperature range; if you have a specific tolerance or specification which must be met, please contact us with your requirements so we can ensure the equipment is designed, tested, and adjusted to meet those requirements.

Packaging & Shipping | Product

Packaging:

Shipping:

Service:

Product Parameters | Product

| Performances | Model | GZ-BDT-VC-02 |

| Temp. Range | RT+40℃-250℃/350℃ | |

| Pressure Range | 101 to 0.1 kPa (760 to 1 Torr) at absolute pressure | |

| Maximum Temp. Reach Time | About 60-80 minutes | |

| Form | Temp. Regulation Accuracy | ±1℃ |

| Internal Material | Stainless steel plate full argon arc welding | |

| External Material | Cold rolled sheet, drug resistant coating on surface | |

| Heat-resistant Material | Glass fiber | |

| Heating Method | Direct heating of the pressure tank wall | |

| Total Power | 8.5KW/10KW | |

| Control Method | Program Operation and Status | 7-inch LCD touch screen control |

| Temp. Control Method | Multi-segment PID algorithm, temperature control accuracy ±0.1℃ | |

| Temp. Setting Method | Digital setup using dedicated operation function menu keys and up/down keys | |

| Operational Function | Fixed-value operation, programmed operation, auto-stop operation, auto-start operation | |

| Program Mode | Customizable upon request | |

| Additional Feature | Deviation correction function, key lock function, power failure compensation function | |

| Heater Loop Control | SSR driver + PIH | |

| Sensor | PT100 Thermocouple | |

| Safety Equipment | Self-diagnostic circuit (temperature sensing abnormality, heater disconnection, automatic overshoot prevention, SSR short circuit) Overshoot prevention, leakage protection switch for overcurrent, key lock function | |

| Norm | External Size(H*W*D/mm) | 1900*988*980 |

| Internal Size(H*W*D/mm) | 600*600*600, shelf size (500*500*500) | |

| Inner Capacity | 216L | |

| Vent | NW25 flange / Rc 1/4 | |

| Nitrogen Inlet | 10mm quick couplings, max.100L/min | |

| Power Current | AC380V 23A(50Hz/60Hz) or as request | |

| Weight | About 426KG | |