Description

Trolley, Roll in Truck in Industrial Ovens

Essential for general heating routines — from drying samples to curing microchips, a precise oven is one of the fundamental instruments every laboratory or workshop should have. GMS truck-in industrial ovens accommodate a variety of thermal processing applications up to 250℃. Our industrial truck-in ovens are ideally suited for drum heating, aging, core hardening, drying, preheating, curing, and component testing. With additional options, these truck-in industrial ovens can also be used for applications such as paint baking, plastic curing, varnish baking, sterilizing, and rubber,silica gel and epoxy curing. Trucks provide a quick and efficient way to load and unload products. Single, double, triple, and quadruple bay trucks are available to match any product load.

FEATURES

- Heavy-duty exterior with heavy-gauge, reinforced, cold-rolled steel

- Baked on white powder-coated finish on the exterior for long-lasting corrosion protection

- Trolley with stainless steel trays with more than 50kg loading capability for each tray

- Adjustable air exchange system which allows fresh air to flow into the oven and exhaust gas get out of the oven

- Aluminum silicate insulation to ensure safe cabinet skin temperature

- Independent, over-temperature protection

- Circuit breaker provided for ground fault protection as standard

- Compact design

- High volume horizontal air recirculation system and electric heating system allow for maximum temperature uniformity in performance

- Excellent reliability and performance ratings

Options | product

- Temperature recorders (paper or paperless)

- Ethernet communications

- Touch screen control panel

Industries | product

- Aerospace

- Automotive

- Defense

- Electronics

- Research & Development

- Rubbers & Plastics

- Semiconductors

- Telecom

- Optical Communication

Applications | product

- Aging

- Annealing

- Testing

- Curing

- Solvents, Coatings, and Paint Curing

Parameters | product

| Model | GM-DKX-01 | GM-DKX-02 | GM-DKX-03 | GM-DKX-04 |

| Interior Dimensions HxWxD | 1550x1200x1000 | 1600x1200x950 | 1200x1300x800 | 1350x1260x1050 |

| Exterior Dimensions HxWxD | 1830x(1500+235)x1140 | 2100x(1480+235)x1100 | 1620x(1600+235)x950 | 1880x(1560+235)x1200 |

| Capacity | 1860L | 1820L | 1250L | 1780L |

| Temp. Range | Room temp. +20~250°C | |||

| Control accuracy | ± 1.0°C | |||

| Temp. Distribution Accuracy | ±3°C (at 100°C), ±5°C (at 150°C) | |||

| Temp. Rising Time | About 30min (Room temp.→150°C). empty chamber | |||

| Operation Function | Optional for fixed temp. or program operation | |||

| Power Source | 3 phase AC380V or as request | |||

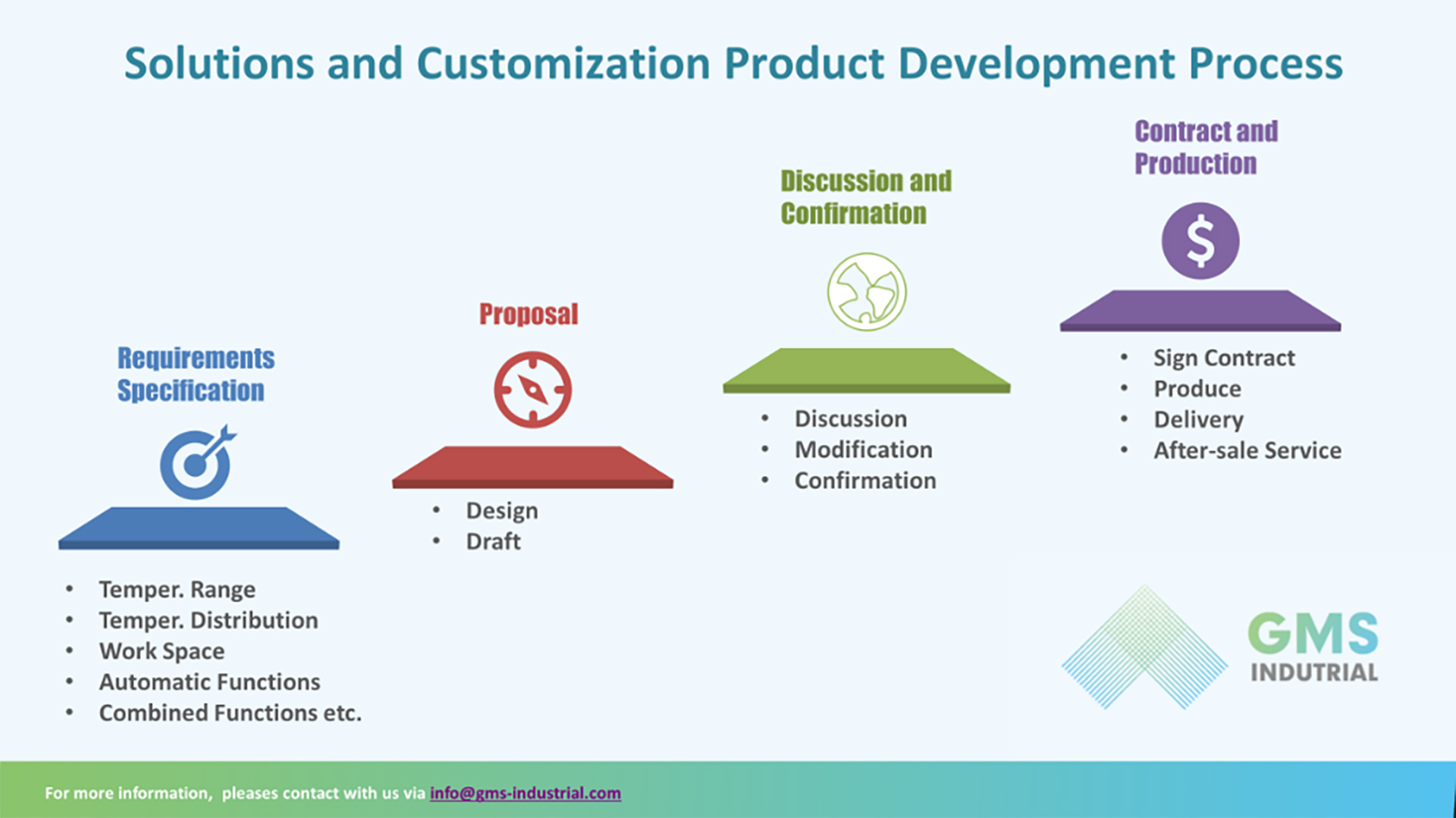

Customization | product

Our custom ovens designed and built to the customers’ exact specifications and heat processing requirements. See examples of these products to view the wide range of industrial heat processing systems we offer and have manufactured for our clients. Our oven systems are quality built, turn-key, efficient, low maintenance. Specific working space size, material, observation window, testing hole, or exterior color are all accepted.

We also offer in heat testing and analysis of your product to ensure the exact oven design for your specific application. If you have a specific tolerance or specification which must be met, please contact us with your requirements so we can ensure the equipment is designed, tested, and adjusted to meet those requirements.