- +91 95435 37321 info@zaratech.biz

- Plot No. 78,79 & 80, Ground floor, Jayam Nagar, Erikkarai Road, Kollacheri, Kundrathur Chennai - 600069

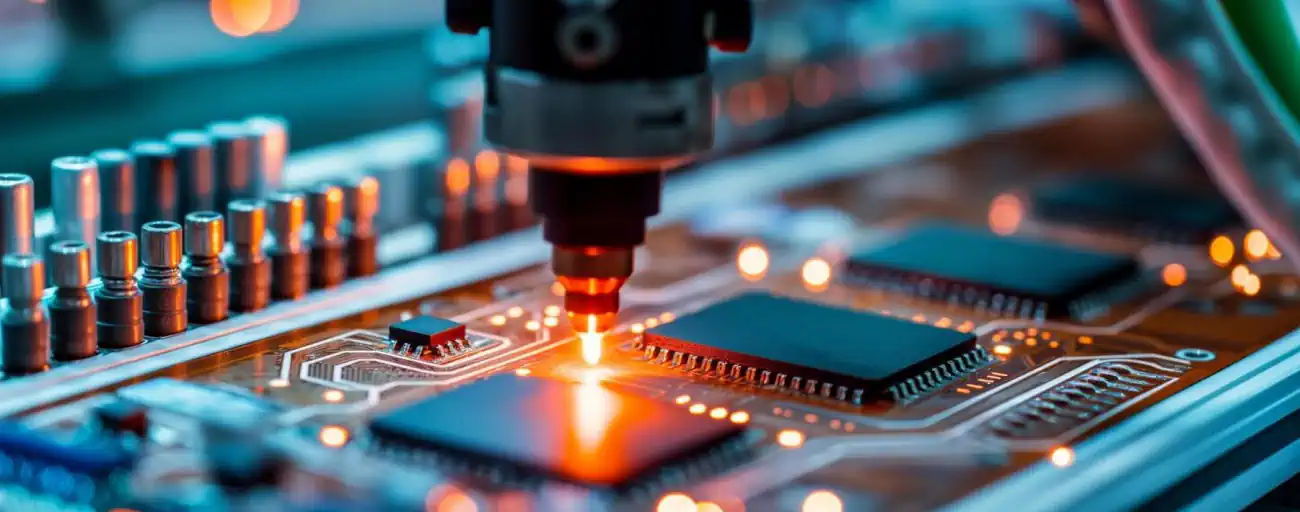

End-to-End Semiconductor Equipment Solutions

Combining technical know-how with tailored support to accelerate innovation and precision in assembly

Your Engineering Ally in Semiconductor Equipment

Delivering smart tools, expert guidance, and scalable solutions to boost performance and reliability

SEMICON EQUIPMENTS

Get equipment that assists IC package assemblies, test, and inspection in your semiconductor industries

SEMICON CONSUMABLES

Cost-efficient and high-performing consumables tailored-made for industrial equipments and needs

TRAINING SERVICES

The primary objective of industrial training is to familiarize students with real-world work scenarios

IC PACKAGE ASSEMBLY

Our experts will address your distinctive needs in the best possible manner in IC assembly.

SEMICONDUCTOR EQUIPMENT SUPPLIER

End-to-End Solutions for Semiconductor Manufacturing

ZARA TECH provides complete equipment solutions for the semiconductor and electronics assembly industries, including die attach, wire bonding, wafer dicing, inspection, and SMT-related systems. We work closely with both multinational and domestic manufacturers across sectors like automotive, telecom, aerospace, and consumer electronics. By understanding customer-specific process needs, we offer customized equipment selection, installation, training, and process optimization support, ensuring successful implementation and long-term productivity.

Local Presence with Global Standards

With a strong presence across India and partnerships with leading international OEMs, Zara Tech bridges global technology with local expertise. Our team of experienced engineers ensures fast response, on-site service, and technical consultation throughout your equipment lifecycle. We are not just suppliers — we are solution providers who believe in creating value through process knowledge, continuous support, and a commitment to customer success in India’s growing semiconductor ecosystem.

TRUSTED

EQUIPMENT

SUPPLIER

IN INDIA

OUR VISION

To deliver next-generation engineering solutions that address critical challenges across industries, enabling innovation, efficiency, and progress.

OUR MISSION

To support the semiconductor, automotive, communication, and SMT/IC packaging sectors with high-performance solutions—enhancing productivity, quality, and cost-efficiency through reliable equipment and expert services.

CORE VALUES

Innovation: We embrace cutting-edge technologies to stay ahead.

Excellence: We deliver quality in every solution, every time.

Commitment: We invest in people, partnerships, and progress.

Integrity: We build trust through transparency and accountability.

Growth: We believe in continuous learning and expansion—of capabilities, teams, and customer value.